A step by step guide to using Ilford’s Multigrade developer, stop bath and fixer in the darkroom, with dilutions, times and handling tips.

ILFORD MULTIGRADE developer is a versatile liquid concentrate developer designed for the dish or tray development of all types of black and white photographic papers, including both resin-coated (RC) and traditional fiber-based (FB) papers. It is typically used at a dilution of 1+9, but for those seeking greater development control and cost-effectiveness, it can be used at a 1+14 dilution ratio.

MULTIGRADE developer is known for its clean and reliable performance, and it maintains excellent keeping properties. When used with most papers, it produces a neutral image tone. This developer is intended for use at ambient room temperatures, typically around 20ºC/68ºF. It is not recommended for high-temperature processes or machine processing applications. Please note that it is not suitable for developing films.

Preparing MULTIGRADE and PQ UNIVERSAL Developers:

To prepare MULTIGRADE and PQ UNIVERSAL liquid concentrates for use, follow these steps:

- Dilution Ratios:

- MULTIGRADE: You can dilute MULTIGRADE at either 1+9 or 1+14.

- PQ UNIVERSAL: For paper, use a dilution of 1+9. For technical films and sheet films, use a dilution of 1+9 or 1+19.

- Timing:

- Prepare the working strength solutions of MULTIGRADE and PQ UNIVERSAL developers just before you need them for your processing session.

- Determine Quantity:

- Calculate the amount of solution required for your session, ensuring it is sufficient to fill the developing dish or tray to about half full.

- Measuring Concentrate:

- Measure out the appropriate amount of concentrate using the smallest measuring cylinder suitable for the liquid volume. For accuracy, it’s easier to measure 100 ml of solution in a 100 ml cylinder than in a larger one.

- Mixing:

- Add the measured concentrate to your mixing vessel. A large measuring jug works well as it allows you to monitor the total solution quantity.

- With an appropriately sized measuring cylinder, measure the required dilution water. Use hot and cold water to achieve the desired working temperature, which is 20ºC/68ºF.

- Rinse the measuring cylinder used for the concentrate into the mixing vessel with some of the dilution water.

- Final Mixing:

- Add the remaining dilution water to reach the final working volume and stir the solution thoroughly. Your developer is now ready for use.

By following these steps, you can accurately prepare the working solutions of MULTIGRADE and PQ UNIVERSAL developers to ensure the best results in your darkroom work.

Please be aware that when used correctly, photographic chemicals are not hazardous. However, for safety reasons, we strongly advise wearing gloves, eye protection, and either an apron or overalls when handling and mixing all chemicals.

Temperature

For dish/tray processing, the working strength developer solutions of MULTIGRADE, PQ UNIVERSAL, and BROMOPHEN should be utilized at the ambient room temperature.

The recommended developing temperature is 20ºC (68ºF) with a tolerance of ±1ºC (2ºF). If slightly lower temperatures are employed, it may be necessary to extend the development time slightly. Conversely, if slightly higher temperatures are used, the development times should be reduced.

It’s essential to note that these developers are not suitable for high-temperature processing. Elevated temperatures can significantly shorten the effective solution life and may result in very brief development times, potentially leading to uneven processing.

Prepare the developer solution

Before commencing the processing, prepare the necessary amount of each processing solution based on the size of the dish/tray used and the number of paper sheets to be processed. Ensure that the volume of the solution is sufficient to fill the processing dish/tray to a depth of approximately halfway, covering the paper entirely during the processing phase.

Additionally, verify the temperatures of all the processing solutions and make necessary adjustments to ensure they are within ±1ºC (2ºF) of the intended processing temperature.

Expose the paper in the enlarger

For a comprehensive guide to using Ilford’s Multigrade filters, see our step by step instructions here.

The paper goes into the tray …

During dish/tray processing, intermittent agitation is used. When processing a single sheet, fully immerse the paper in the developer and gently rock the dish from side to side while being cautious to prevent spillage. This method of agitation should be used for all subsequent processing steps.

When developing multiple sheets of paper simultaneously, intermittent agitation is achieved through interleaving. To interleave the paper, insert the sheets into the solution one by one, with the emulsion side facing down.

Once all the sheets are in the solution, take the bottom sheet and place it on top of the stack of sheets in the dish/tray. Continue this process, moving the sheet from the bottom to the top, until the designated processing time is complete. Utilize this method of agitation for all subsequent processing steps.

The number of sheets that can be interleaved at one time depends on individual preference, but exercise caution, as too many sheets with inadequate agitation can result in uneven processing.

It’s important to note that traditional fiber-based (FB) papers are more challenging to interleave compared to waterproof resin-coated (RC) papers, as FB papers absorb more liquid and become more pliable when wet. Handle them carefully to avoid damage.

To prepare for the next step, remove the paper(s) from the dish/tray approximately 10 seconds before the development time ends, allowing the developer to drain before placing it in the stop bath.

ILFORD Development times

| RC paper | FB paper | ||||||||

| RC paper | Dilution | ºC/ºF | Time (min:sec) | FB paper | Dilution | ºC/ºF | Time (min) | Range | |

| Developer Liquids | Developer Liquids | ||||||||

| MULTIGRADE | 1+9 | 20/68 | 1:00 | MULTIGRADE | 1+9 | 20/68 | 2 | 1 1/2–3 | |

| MULTIGRADE | 1+14 | 20/68 | 1:30 | MULTIGRADE | 1+14 | 20/68 | 3 | 2-5 | |

| PQ UNIVERSAL | 1+9 | 2:00 | PQ UNIVERSAL | 1+9 | 20/68 | 2 | 1 1/2–3 | ||

| Developer Powder | Developer Powder | ||||||||

| BROMOPHEN | 1+3 | 20/68 | 2:00 | BROMOPHEN | 1+3 | 20/68 | 2 | 1 1/2–3 |

RC paper: Approximately double these times are recommended with MULTIGRADE RC COOLTONE paper to obtain the coolest image colour

For correctly exposed fiber-based (FB) prints, you can expect the image to start emerging within 35 seconds when using these developers. It’s worth noting that you can extend the development time up to 6 minutes without observing any significant alterations in contrast or fog.

When you’re processing a substantial quantity of either resin-coated (RC) or FB prints in a batch, it could be beneficial to slightly reduce the exposure and prolong the development time. This approach helps maintain consistent results across multiple prints in the batch processing workflow.

Developer capacities

The following table gives the developing capacity of 1 litre of working strength developer

| ILFORD developer | Dilution | 20. 3×25. 4cm (8×10 inch) ILFORD prints RC paper | 20. 3×25. 4cm (8×10 inch) ILFORD prints FB paper |

| Liquids | |||

| MULTIGRADE 1+9 | 100 | 50 | |

| MULTIGRADE 1+14 | 70 | 40 | |

| PQ UNIVERSAL 1+9 | 70 | 45 | |

| Powder | |||

| BROMOPHEN 1+3 | 70 | 45 |

Approximately half these capacities are achieved if only MULTIGRADE RC COOLTONE is processed due to the longer development times recommended with MULTIGRADE RC COOLTONE paper.

Stop bath

This step stops the developer from acting on the paper. Agitate the paper in the stop bath for about 30 seconds.

| ILFORD stop bath | Dilution | ºC/ºF | Time (sec.) |

| ILFOSTOP | 1+19 | 18–24/64–75 | 10 |

| ILFOSTOP Pro | 1+19 | 18–24/64–75 | 10 |

Into the fixer …

The third tray in the darkroom will have a solution of fixer prepared. After the print has had a bath in the Stop solution, grab it with rubber-tipped tongs and move the print from the Stop tray into the Fixer tray.

| Dilution | ºC/ºF | RC time (min.) | FB time (min.) | |

| Liquids | ||||

| ILFORD Rapid Fixer | 1+4 | 18–24/64–75 | 1/2 | 1 |

| ILFORD Rapid Fixer | 1+9 | 18–24/64–75 | 1 | 2 |

| HYPAM | 1+4 | 18–24/64–75 | 1/2 | 1 |

| HYPAM | 1+9 | 18–24/64–75 | 1 | 2 |

| Powder | ||||

| ILFOFIX II | stock | 18–24/64–75 | 2 | 3 |

And now to wash the print …

This final step can be handled with rubber gloved hands – no need to use tongs.

Washing RC paper

Wash the print in clean running water above 5°C or 41°F for 2 minutes. Either hang the print to dry, careful not to imprint peg marks onto the wet paper, or place the wet print in a rack made for the purpose.

When a quick print is crucial, immerse ILFORD resin-coated papers in running water and vigorously wash them for 30 seconds.

Be cautious about extended soaking in water, as it may lead to edge penetration and curling of resin-coated papers. To prevent these issues, it’s advisable to avoid wet times exceeding 15 minutes.

Washing FB paper

Wash the print in clean running water above 5°C or 41°F for 1 minute. Hang the print to dry, avoiding peg marks onto the wet paper, or place the wet print in a drying rack.

Avoid washing ILFORD papers together with certain non-ILFORD papers that tend to develop a yellowish tint during prolonged washing. This mixing can result in a hazy or blooming effect over the black areas of the prints.

While conventional processing of fiber-base papers typically doesn’t require a washing aid, its inclusion can reduce final wash times, saving both time and water. If a hardening fixer has been utilized, it’s advisable to use a washing aid, especially as hardened prints necessitate longer washing durations.

When employing ILFORD WASHAID, follow these steps: First, wash prints for a minimum of 5 minutes in running water before introducing the washing aid. Afterward, proceed to wash the prints in running water for a total duration of 20 minutes.

Ilford Washaid is used at a dilution of 1+4 at room temperature for 10 minutes.

Print drying

We’ve all seen the movies of darkrooms with prints hanging out to dry. This can get complicated, quickly. A purpose built drying rack will stack the prints neatly. Some well equipped commercial darkrooms have drying cabinets to quickly dry the finished print.

If in a desperate hurry, such as a newspaper deadline, a hand dryer is often used on the prints.

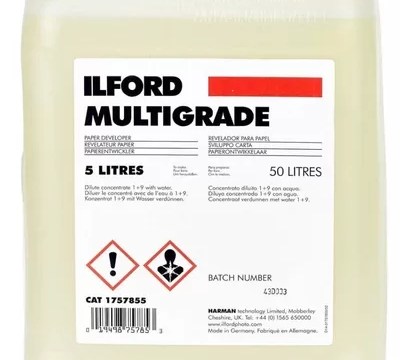

Availability

MULTIGRADE developer is offered in various bottle sizes, including 500ml, 1 litre, 2.5 litres, 5 litres, and a 10 litres “bag in box” carton. A 1 litre bottle of MULTIGRADE developer is sufficient to prepare a working strength solution at 1+9, capable of processing either 1000 sheets of 20.3×25.4cm (8x10in) resin-coated (RC) paper or 500 sheets of 20.3×25.4cm (8x10in) fiber-based (FB) paper.

Storage

Unopened bottles of MULTIGRADE and PQ UNIVERSAL developer concentrates, stored in a cool environment between 5–20ºC (41–68ºF), will maintain their quality for up to 2 years. After opening, it is advisable to use the concentrate entirely within six months. Keep all bottles tightly sealed until they are used to preserve their freshness.

Visit the Ilford store on Amazon

Related stories

How To Make A Print Using Multigrade Filters And Paper

What is Ilford Multigrade developer & paper

History of variable contrast paper in the darkroom

Guide to Collecting Vintage Film Cameras

Hasselblad camera ° medium format film camera

Polaroid Land cameras ° Polaroid instant camera